Which finishes and coatings are used in steel fabrication? Find out more about how to select the best coating for your steel project.

Different Types of Metal Finishes

Metal finishing is the final stage of production, which gives both aesthetics and environmental protection. It is also used to reduce surface roughness beyond the limits of machining operations for parts that must mate or seal.

It also includes metal descaling, deburring, and cleaning procedures. In summary, a variety of metal finishing processes are used to achieve a variety of purposes.

Metal finishing treatments often provide increased durability, enhanced aesthetic appeal, improved electrical conductivity, higher electrical resistance, stronger chemical resistance, and higher tarnish resistance.

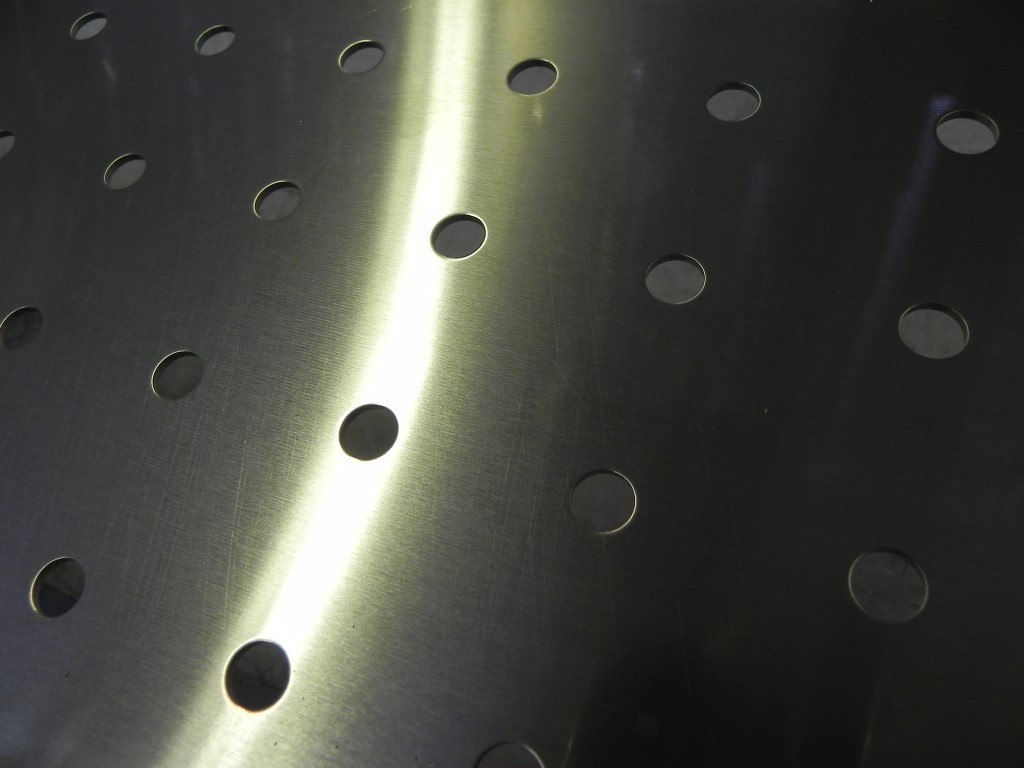

Brushing

Metal finishing using brushes, as opposed to plating, is a successful way to get rid of surface flaws.

To smooth out a product's exterior, these finishing machines provide a surface texture with a consistent, parallel grain. To do this, a wire brush or abrasive belt is typically used.

Additionally, the sole direction of the belt or brush might produce edges that are perpendicular to the grain but somewhat rounded. Additionally, certain welding procedures create slag, which is removed using wire brushing along with scale and grit from metal surfaces before cleaning. Before plating or coating, oil residue left over from machining, forming, and other operations are cleaned in chemical baths and acid baths.

Grinding

Abrasive wheels are used in grinding machines to level up surfaces; there are several types of grinding machines designed to provide varying degrees of finite smoothness.

Grinding is used to decrease surface roughness left over after machining as well as as a last step in the machining process to close in on a tolerance.

A surface grinder is the most common type of grinding equipment, however, there are several speciality grinders in use, such as centerless grinders and Blanchard grinders, with precise Blanchard grinding being a popular metalworking method for big items.

Polishing

These abrasive techniques are used to smooth out metal surfaces after machining. The most demanding machining methods (reaming, broaching), which produce surface finishes of 16-125 -in, quantify roughness in micro-inches.

Using abrasive wheels or mounted points, precision or fine grinding can decrease surface roughness to 8-16 in. In addition, abrasive powders are used to polish objects.

By rubbing mating components against one another or passing a matching shape through a hollow, honing and lapping employ abrasive substances to reduce the surface roughness of the parts.

Blasting

Sandblasting equipment, for example, is commonly used in applications that need a uniform matte finish.

Sandblasting is a high-speed procedure that drives sand, steel shots, metal pellets, or other abrasives onto a substrate; this produces a smooth, clean product texture, especially in soft metals.

Vibratory Finishing

Vibratory finishing machines are used for deburring goods, as well as to remove sharp edges, sprue, and other debris.

They place the pieces within an abrasive pellet-filled drum and use tumble vibration to generate a consistent random texture. The cycle speed and amount of vibration of the machine are generally changeable, allowing successful treatment of a wide range of small- to large-sized items.

Coating

Water- and oil-based paints are used to protect metals against corrosion at a low cost. Special paints for extreme conditions, such as anti-fouling paints for maritime uses, are available. Powder coating creates a decorative surface that is comparable to paint but lasts longer.

This is an electrostatic method in which a charge applied to the substrate attracts powder particles.

A textured powder-coat finish is excellent for concealing surface flaws - aluminium is frequently anodised, which is a chemical surface treatment, to offer corrosion protection, aesthetic effects, or, in the case of hard-coat anodising, higher wear resistance.

Heat Treating

Heat treatment is a key stage in many metal production procedures because it is utilised to get desirable features in the material once its finished shape is achieved.

For example, when gears are cut, they are frequently hardened using an inductive or flame heating process to improve wear resistance at the tooth surfaces while also strengthening the underlying teeth.

Hardening often involves a quenching procedure, which is an important stage in altering the metal's grain structure; heat treatment is also used to eliminate any residual tensions left over after manufacture.

Plating

In metal plating, tiny layers of metal, such as zinc, nickel, cadmium, or chromium, are applied to or changed from the surface of substrates using chemical baths.

Electroless plating covers the substrate using an autocatalytic method in which the substrate catalyses the process as opposed to electroplating, which coats the substrate with an electric current. Plating is nearly always done by plating service providers with industry expertise because it is a chemically demanding, extensive method.

The longevity, corrosion resistance, surface friction, and general aesthetic of a product may all be enhanced by metal plating. When it comes to galvanised metal, the zinc coating acts as a sacrificial anode, corroding while protecting the underlying substrate's structural integrity.

However, it is uncommon to eliminate surface flaws with plating equipment. Small steel components like bolts and washers can be coated with a corrosion-resistant zinc-iron alloy through a technique called sherardising.

To provide an extremely corrosion-resistant finish, parts are tumbled in a heated drum containing zinc dust. A barrel-finishing machine is a quick and effective coating option for high-volume manufacturing runs.

Hot Blackening

Hot blackening machines apply a thin coating of black oxide to the surface of a product to provide a matte black finish with exceptional abrasion resistance.

It is a high-temperature hot finishing technique that involves inserting the product into a succession of tanks that contain cleansers, caustics, and coolants; the most popular applications for hot blackening are automobile components, tools, and guns.

How to Select the Best Coating for your Steel Project

The finishing of a steel project is equally as vital as the production process. When choosing the optimum finish, examine if the finish is being done for merely cosmetic or for added corrosion protection. If the proper finish is not done, there is a strong risk the product will not last and you will immediately notice symptoms of degradation.

Shot Blasting

First and foremost, prepare! To get a nice finish, all mill finish and scale, which is typical on big lengths of steel, must be removed.

Imperfections can be removed to create a suitable foundation (also known as a 'etch') for the paint or coating to adhere to. Shot blasting is the method of removing contaminants by using abrasive particles under high pressure.

To blast abrasive particles onto metal profiles, a fast revolving throwing wheel enclosed in a specific steel framework that directs the metal is employed. Rust and old paint are also removed by shot blasting.

Powder Coating

Powder coating is a new dry finishing technology that is gaining popularity. Powder coating is popular due to its versatility and ability to provide a high-quality, uniform surface.

Due to its capacity to quickly cover large areas, it is also a good choice for large-scale projects. Powder coating is also popular owing to its practicality, durability, and appealing, eye-catching finish, which comes in a variety of colours.

Powder coatings are created by combining polymer resin systems with curatives, pigments, and other components. Powder coating is frequently done using an electrostatic spray deposition (ESD) process; this method produces a highly durable, uniform coating that protects the metal in outdoor locations exposed to the weather. Powder coating is a cost-effective approach to treating aluminium, mild steel, and stainless steel due to the manner of application.

Galvanising

Galvanising is a protective coating applied to mild steel or carbon steel in the industrial sector. A coating of zinc is applied using a hot dipping procedure to coat the metal and prevent rusting and corrosion.

Galvanising is a flexible procedure that provides corrosion protection for building materials exposed to air conditions. Galvanising is a highly adaptable solution since it can be applied to big amounts of metal but is also cost-efficient when used on smaller things. Once galvanised, the steel will not require any additional care and will last a lifetime.

Stainless Steel

A form of an iron alloy called stainless steel has at least 10.5% chromium in it. A thin oxide coating produced by chromium on the surface of the steel shields the metal from surface corrosion; this results in increased corrosion resistance as a result of higher chromium concentration.

Stainless steel offers a variety of surface finishes, some of which are applied later in the manufacturing process. The choice of surface treatment has a significant impact on the corrosion resistance of the stainless steel surface. Something with a rough surface finish may be more prone to corrosion. Stainless steel may complement a wide range of architectural elements - furthermore, it is extremely durable and requires no extra maintenance after installation.

Warm to Touch

'Warm to Touch,' like powder coating, is a plastic coating applied through a spray system to surfaces such as handrails to provide additional comfort. The high-quality PVC coating prevents heat conduction away from the hand.

The material is UV stable and weather resistant, making it suitable for both outdoor and indoor uses, as well as industrial and commercial settings. It is available in several colours and the finished product is extremely long-lasting and has a flush, uniform surface with no snagging.

Zinc Plating

The technique of electroplating zinc onto mild steel or iron components is known as zinc plating. Zinc plating serves as a sacrificial covering that corrodes slowly over time, preserving the steel beneath.

Another significant advantage of zinc plating is that the coating itself improves the aesthetic of the base metal; transparent zinc plating has an appealing brilliant silver and blue appearance.

The material's condition is critical for achieving the optimum zinc plating outcomes. The finest polish is possible with clean, rust-free metal; the zinc layer is passivated for improved corrosion resistance.

Epoxy Coating

Wet paint systems, commonly known as Epoxy Paint, are paint systems that consist of acrylic paint melamine and a hardener resin; when these two resins are mixed, they cause a chemical reaction that results in a hardened solution.

Many industrial coating applications, such as steel, aluminium, and concrete, favour epoxy paint solutions. Epoxy coatings are resistant to numerous corrosive chemicals and provide excellent protection against abrasion, corrosive fluids, and severe temperatures.

When epoxy dries, it hardens into a strong, completed surface that will persist for many years, even under harsh environments.

Are you looking for RSJ steel beam suppliers in London and the surrounding areas? Follow the link below to discuss your project.